| 3. |

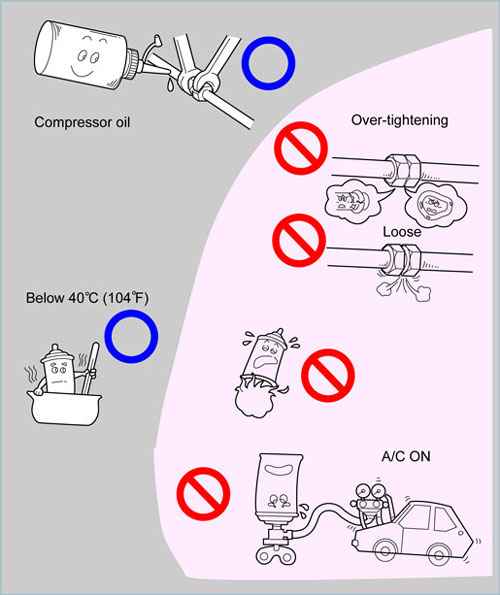

When tightening connecting parts

|

|

Apply a few drops of compressor oil to all O-rings to prevent leakage of the refrigerant gas. |

|

First tighten all the nut using two open-end wrenches to avoid twisting the pipes/tubes. . |

|

Finally tighten the O-ring fittings or the bolted type fittings to specification using a torque wrench |

|

| 4. |

When handling bulk refrigerant |

|

The container must never be heated. |

|

Containers must be kept below 40°C. |

|

| 5. |

When A/C is on and refrigerant gas is being replenished

|

|

If there is not enough refrigerant in the refrigeration circuit, lubrication may become insufficient and the compressor may be damaged. |

|

If the high-pressure side manifold gauge valve is opened, a reverse flow of refrigerant will occur possibly causing the bulk refrigerant container to rupture, so only operate the low-pressure side manifold gauge valve. |

|

If the bulk refrigerant container is inverted and refrigerant is charged in a liquid state into the low-pressure side, the liquid refrigerant will enter the compressor and damage it, so the refrigerant must be charged in a gaseous state. |

|

Be careful not to over charge the refrigerant as this can cause trouble such as inadequate cooling, poor fuel economy and engine overheating. |

|