|

|

|

|

|

Refrigeration System

|

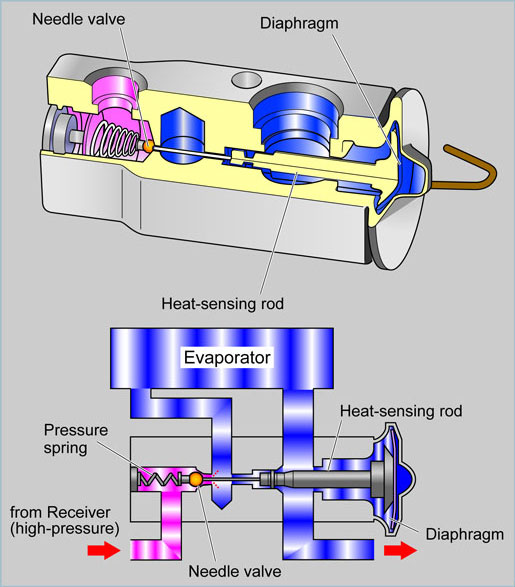

Expansion Valve (Box Type)

|

|

|

| 1. |

Function

|

|

After leaving the receiver dryer, the expansion valve injects the high-temperature, high-pressure liquid refrigerant from the small hole at the needle valve causing the refrigerant to suddenly expand and to change into a low-temperature, low-pressure mist refrigerant. |

|

The expansion valve continually adjusts the amount of refrigerant supplied to the evaporator according to the cooling load. |

|

| 2. |

Construction

|

| The valve directly detects the refrigerant temperature (cooling load) around the outlet of the evaporator by the heat-sensing rod and transmits it to the gas inside the diaphragm. The change of the pressure of the gas due to the temperature change and the balance between the pressure of the outlet of the evaporator and that of the pressure spring moves the needle valve to adjust the amount of the refrigerant flow. |

| 3. |

Operation

|

The temperature around the outlet of the evaporator changes according to the cooling load.

|

The temperature around the outlet of the evaporator changes according to the cooling load. When the cooling load is small, the temperature around the outlet of the evaporator goes down, and the temperature transmitted from the heat-sensing rod to the gas inside the diaphragm also goes down, which makes the gas contract. As a result, the needle valve is pressed by the outlet refrigerant pressure of the evaporator and the pressure spring pressure, and moves to close the valve, decreases the amount of refrigerant flow and lowering the cooling capability |

|

If the cooling load is great, the temperature around the outlet of the evaporator increases and the gas expands. As a result, the needle valve moves against the pressure spring. Opening the valve increases the amount of refrigerant circulating in the system and increases the cooling capability |

|

|

(29)

|

|